Problem:

Frequent production disruptions due to stoppages of

the wet grinding process in the mining plant caused

by varying ore quality, which can only be evaluated

by offline chemistry laboratories.

Impact:

$30K per hour lost in production and massive

clean up and recovery effort to restore the process

Solution:

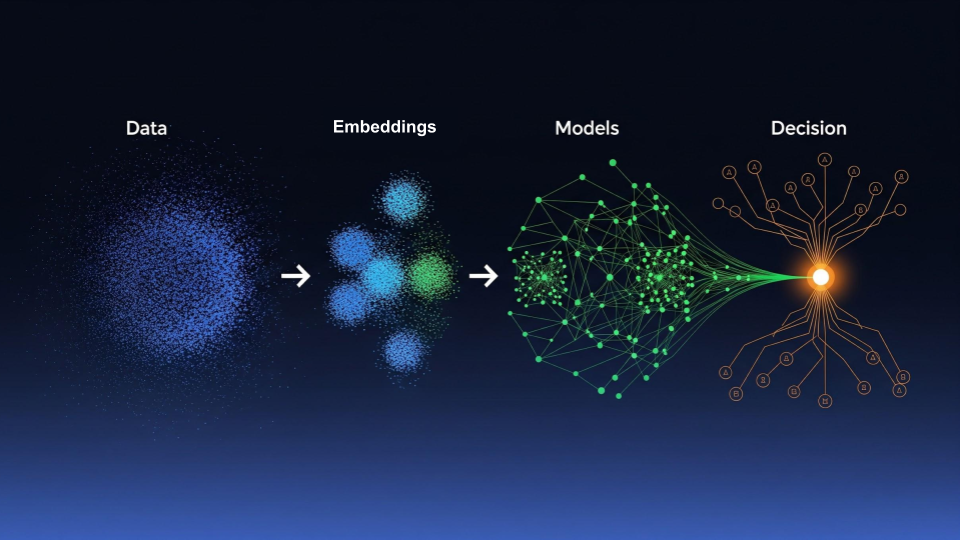

Time Series Intelligence uses SCADA data to estimate

ore grade and give real-time alerts about bad ore

entering the process. This way, they can take action

quickly to prevent any stoppages.

Watch this ->

'%3e%3cg%20id='SVGRepo_bgCarrier'%20stroke-width='0'/%3e%3cg%20id='SVGRepo_tracerCarrier'%20stroke-linecap='round'%20stroke-linejoin='round'/%3e%3cg%20id='SVGRepo_iconCarrier'%3e%3cg%20id='Train'%20transform='translate(-642.389%20-380.3)'%3e%3cpath%20id='Path_69'%20data-name='Path%2069'%20d='M686,393.4H642.9a.5.5,0,0,0,0,1H686a.5.5,0,0,0,0-1Z'/%3e%3cpath%20id='Path_70'%20data-name='Path%2070'%20d='M644.9,391.5h40.3a.9.9,0,0,0,.9-.9l-.5-8.4a.9.9,0,0,0-.9-.9H679l-1-1h-5l-1,1h-9.2l-1-1H657l-1,1h-1.4a6.069,6.069,0,0,0-4.9,1.7l-6.4,5.7C643.2,388.7,640.5,391.5,644.9,391.5Zm32.2-6.7h6v3h-6Zm-8.5,0h6v3h-6Zm-8.5,0h6v3h-6Zm-8,0h5.3v3h-8.8Z'/%3e%3c/g%3e%3c/g%3e%3c/svg%3e)